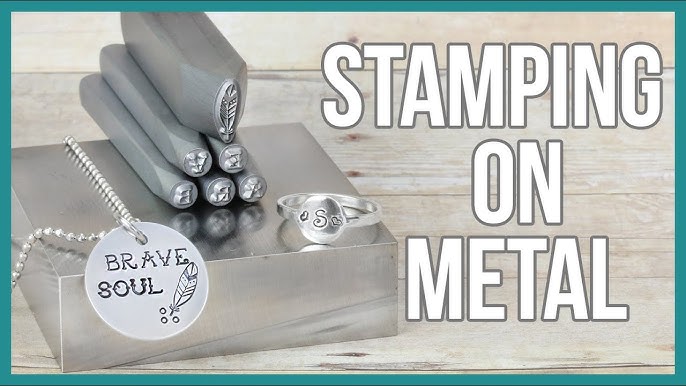

Unlocking the Power of Metal Stamping: Techniques for Enhanced Item Advancement

In the world of manufacturing, the utilization of steel stamping holds a substantial area as a result of its flexibility and performance in creating detailed parts and parts. However, truth possibility of metal stamping stays untapped by several companies seeking to improve their product advancement processes. By discovering advanced techniques and strategies tailored to enhance layout, material choice, manufacturing effectiveness, and quality assurance, companies can unlock a wide range of opportunities to boost their products to brand-new heights of technology and performance.

Benefits of Steel Stamping

Steel marking deals a economical and reliable approach for generating top quality metal elements. This production procedure entails shaping, cutting, or developing steel sheets making use of a marking press (Metal Stamping). Among the vital advantages of steel marking is its capacity to develop intricate geometries with high precision and consistency. This is particularly useful for industries such as automobile, aerospace, and electronic devices, where detailed steel components are frequently needed.

Additionally, steel stamping enables high-volume production, making it excellent for tasks that need huge amounts of metal components. The speed and repeatability of the marking process not only make sure price financial savings yet additionally add to faster turn-around times for production orders. Furthermore, using automatic tools in steel stamping aids lessen the risk of human mistake, causing enhanced total item quality.

Layout Optimization Strategies

With cautious factor to consider of material buildings and geometric configurations, style optimization strategies play an essential function in boosting the efficiency and performance of steel stamping processes. By tactically examining variables such as product density, kind, and stamina, makers can tailor the style to maximize the performance of the marking procedure. Utilizing simulation software application, designers can predict exactly how various layout variations will act under numerous stamping conditions, enabling the identification of prospective problems prior to production begins.

Moreover, including features like fillets, chamfers, and embosses into the style can boost the general top quality of the stamped component while lowering the danger of flaws such as splitting or deforming. Additionally, maximizing the format of functions on the part can enhance the product circulation throughout stamping, resulting in more constant and accurate end results.

In significance, style optimization techniques make it possible for suppliers to tweak their metal marking procedures, causing enhanced product top quality, boosted production performance, and inevitably, a much more competitive position on the market.

Material Selection Approaches

Style optimization methods in metal marking procedures heavily depend on tactical material option methods to make sure the preferred performance and efficiency of the manufactured components. The option of product in steel marking is essential as it directly impacts the high quality, durability, and total performance of the end product. When choosing the appropriate product for a particular task, aspects such as mechanical buildings, deterioration, cost-effectiveness, and formability resistance need to be thought about.

Furthermore, cost-effectiveness plays a considerable function in material selection approaches. Stabilizing the performance requirements with the total expense of materials is important to make certain the economic viability of the production procedure. Additionally, considering aspects like recyclability and environmental influence can better improve the sustainability of the chosen product. By very carefully evaluating these facets, makers can optimize their product selection strategies to attain exceptional item additional info quality and functional effectiveness.

Enhancing Manufacturing Efficiency

Performance in production processes is a critical aspect for ensuring cost-effectiveness and prompt delivery of premium steel marked components. special info To boost production efficiency in metal stamping, a number of methods can be carried out.

In addition, carrying out automation and robotics in metal stamping operations can considerably enhance productivity and consistency while reducing labor prices. Automated systems can do repeated tasks with high accuracy and speed, leading to boosted manufacturing efficiency and greater outcome rates. Spending in contemporary marking devices with advanced attributes, such as servo-driven presses and quick die change systems, can better enhance manufacturing processes and reduce downtime.

Furthermore, developing clear communication networks and promoting collaboration in between style, engineering, and manufacturing teams is crucial for recognizing potential traffic jams and carrying out continuous enhancements in the production process - Metal Stamping. By embracing lean production principles and leveraging technology innovations, makers can unlock the complete capacity of steel stamping processes and attain higher manufacturing effectiveness

Quality Assurance and Evaluation Techniques

To ensure the consistent manufacturing of top quality steel stamped parts, strenuous high quality control and examination approaches play a crucial duty in validating the accuracy and stability of the manufacturing procedure. Quality control in official statement metal marking involves a series of organized checks and procedures to assure that each part fulfills the specific requirements. In addition, progressed technologies such as automated optical assessment systems and coordinate measuring devices are significantly being used to improve the precision and efficiency of quality control procedures in steel marking.

Conclusion

In final thought, steel stamping offers countless benefits such as cost-effectiveness, precision, and adaptability in item growth. By executing style optimization strategies, picking appropriate materials, and improving manufacturing performance, manufacturers can attain greater high quality items with reduced preparations. Quality assurance and inspection techniques play a crucial role in guaranteeing the final products satisfy the needed requirements. Generally, opening the power of metal marking calls for a critical approach to enhance product development processes.

Metal stamping deals a cost-efficient and reliable approach for generating high-quality metal components.Furthermore, steel marking enables for high-volume production, making it suitable for tasks that require huge amounts of steel parts.With careful factor to consider of material residential properties and geometric setups, design optimization strategies play a vital role in boosting the effectiveness and functionality of steel stamping procedures.Design optimization techniques in steel stamping procedures heavily depend on tactical product choice strategies to make certain the desired efficiency and performance of the produced components. The option of product in metal marking is vital as it directly affects the top quality, toughness, and overall performance of the last product.

Comments on “Exactly How Metal Stamping Reinvents Production Efficiency”